To Assure.

Tetrahedron International Professional Services Pty Ltd (TIPS)

Galvanizing & Painting Inspection Services

At TIPS, we provide expert Galvanizing and Painting Inspection services across Western Australia, ensuring corrosion protection systems meet the highest quality and compliance standards. Our qualified inspectors perform thorough assessments of surface preparation, coating application, thickness, adhesion, and overall finish, in accordance with relevant Australian and international standards such as AS/NZS 2312, AS 1627, and ISO 12944. Whether it's hot-dip galvanizing, industrial painting, or protective coatings, we help clients across sectors like infrastructure, mining, oil & gas, and construction maintain durability, safety, and long-term performance of their assets. With a commitment to precision, compliance, and excellence, TIPS delivers inspection solutions that safeguard your projects from premature failure and environmental exposure.

Pre-Inspection & Surface Preparation Assessment:

At TIPS, our Galvanizing and Painting Inspection process begins with a comprehensive pre-inspection of all steel components before any surface treatment takes place. This critical first step ensures that the materials meet project specifications and are free from contaminants such as oil, grease, rust, or mill scale that could affect the adhesion of galvanizing or paint coatings. For painting systems, we pay particular attention to the surface preparation, which is a key factor in coating performance and longevity. Our inspectors verify that abrasive blasting has achieved the correct surface profile and cleanliness as per AS 1627 standards. We also check for sharp edges, weld spatter, and other surface irregularities that must be removed prior to coating. This thorough inspection lays the foundation for a successful and long-lasting protective coating or galvanizing system.

Painting & Coating Application Monitoring:

For projects involving protective painting or industrial coatings, we provide end-to-end inspection throughout the coating application process. Our inspectors verify that all coating materials are stored, mixed, and applied according to the manufacturer’s instructions and project specifications. Environmental factors such as humidity, surface temperature, and dew point are carefully monitored to ensure they are within acceptable ranges for application. We check the proper application of each layer—primer, intermediate, and topcoat—to ensure the system is built up correctly. Our inspections follow standards such as ISO 12944 and AS/NZS 2312, which define coating systems for steel structures in various environments. Whether using epoxy, polyurethane, zinc-rich primers, or specialized coatings, our goal is to ensure a flawless application that provides lasting protection against corrosion and environmental exposure.

Final Inspection & Detailed Reporting:

Once galvanizing or coating processes are complete, we conduct a final inspection to verify full compliance with project specifications, industry standards, and client requirements. This includes a final visual assessment, confirmation of coating thickness, review of defect rectifications (if any), and verification of surface condition. We compile all inspection data into comprehensive reports that include photographic evidence, testing results, material certifications, and conformance statements. These reports are delivered promptly to support project documentation, quality assurance records, and audits. At TIPS, we pride ourselves on transparency, accuracy, and professionalism—ensuring our clients receive not only high-quality inspection services but also the documentation needed to move forward with confidence. Our inspections help guarantee long-term asset protection, reduce maintenance costs, and support the overall success of your project.

Galvanizing Inspection:

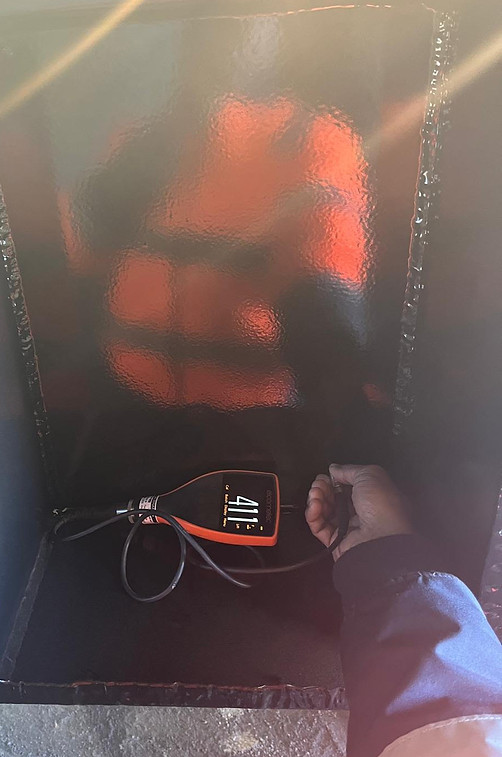

Our galvanizing inspection services focus on ensuring compliance with AS/NZS 4680, which governs the hot-dip galvanizing of steel products in Australia. During this phase, our qualified inspectors observe the galvanizing process to ensure proper immersion times, coating uniformity, and bath temperature controls are maintained. After galvanizing, we conduct detailed visual inspections to check for surface defects such as blisters, roughness, excessive zinc build-up, bare spots, or flaking. Using calibrated coating thickness gauges, we perform zinc coating thickness measurements to verify that the galvanized layer meets both minimum and maximum requirements for effective corrosion protection. Our inspections ensure the galvanized surface is not only visually acceptable but also capable of withstanding harsh environmental conditions, making it ideal for structural applications in coastal, industrial, and rural regions across Australia.

Dry Film Thickness (DFT) & Adhesion Testing:

After coating is applied, our team conducts critical post-application tests to confirm the quality and effectiveness of the protective system. One of the most important checks is the measurement of Dry Film Thickness (DFT), which ensures that the coating has been applied within the specified range for durability and performance. Using calibrated digital gauges, we take multiple readings across different areas to ensure uniform coverage. In addition to DFT, we perform adhesion tests such as cross-cut or pull-off adhesion testing, depending on the coating system and project requirements. These tests evaluate how well the coating adheres to the substrate and its ability to withstand mechanical stress, thermal cycles, and environmental exposure. These precise and reliable tests help prevent premature coating failure, saving time and cost in the long run.

Why Choosing Us

-

Certified Inspectors

Our team includes certified and experienced professionals who ensure compliance with Australian and international standards.

-

Complete Quality Coverage

We offer end-to-end inspection from surface preparation to final coating, reducing risks and ensuring durability.

-

Advanced Testing Methods

We use state-of-the-art equipment for accurate DFT, adhesion, and surface profile testing.

-

Detailed Reporting

Our inspections include clear, traceable reports with measurement data, photos, and compliance documentation.

-

Industry Expertise

We tailor our services to meet the specific needs of industries like infrastructure, mining, oil & gas, and construction.